A Great Partnership of Technology!

AppliCad and Swenson Shear

Great partnerships often result in two plus two equals five. The partnership

of the Swenson Shear and

AppliCad's

Roof Wizard certainly creates added value for a roofing contractor

far in excess

of the value of the component

parts.

The savings are real and you may recover the initial investment

from the savings on your first job!

The process is simple -

![]() Model the roof

Model the roof

![]() Check the model

is correct

Check the model

is correct

![]() Simulate the

laying of the roof panels and nest the panels

Simulate the

laying of the roof panels and nest the panels

![]() Create the cutting

lists and panel placement drawing

Create the cutting

lists and panel placement drawing

![]() Order the panels

cut to length (according to the automatically generated cut list)

Order the panels

cut to length (according to the automatically generated cut list)

![]() Cut the panels

Cut the panels

![]() Fit the panels

Fit the panels

No other process combination can make such a valuable contribution to the roofing contractor's bottom line

![]() reduces

waste

reduces

waste

![]() improves

efficiency on the job site

improves

efficiency on the job site

![]() improves

job safety

improves

job safety

![]() reduces

strain on the installation crew

reduces

strain on the installation crew

![]() makes a

cleaner job site

makes a

cleaner job site

![]() reduces

bin costs

reduces

bin costs

How?

Process - Benefit

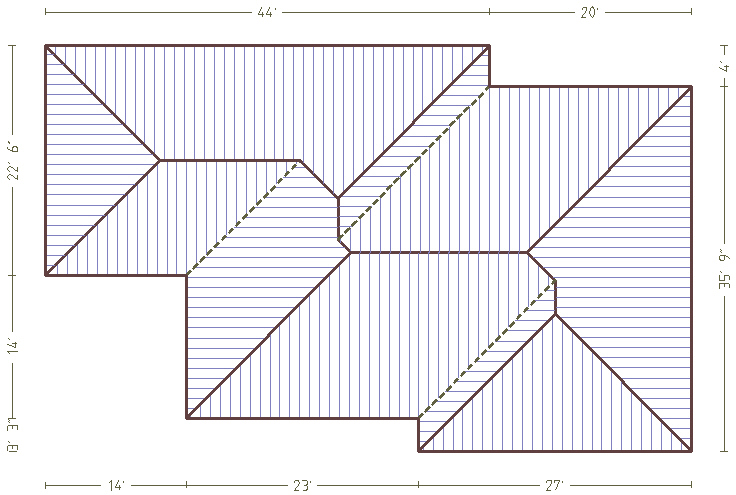

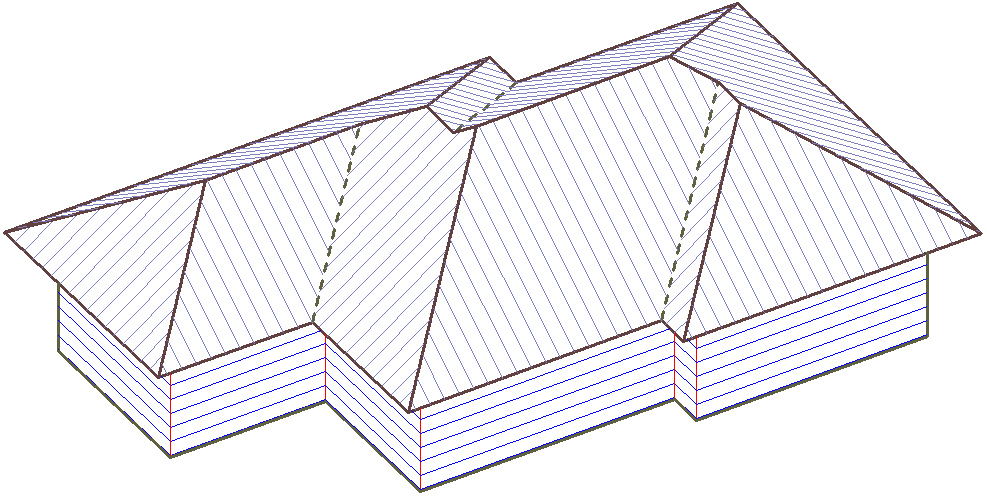

Model the roof in 3D - A more accurate take-off and cutting list

Check the model's accuracy - accurate model geometry allows software to generate correct panel cutting list

Compare model with architect's plan - 3D model allows review from any point of view, confirming model geometry

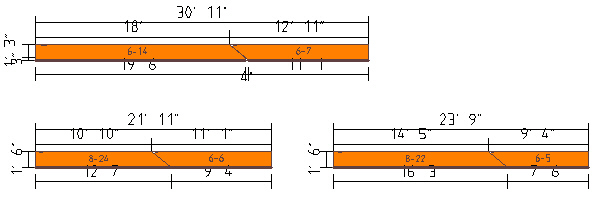

Simulate application of roof panels - generates precise cutting list

Linear Nesting joins panels that may come from a single panel -

one cut, two panels, NO WASTE! This is

reproduced over the entire roof

- every panel is compared with every other panel to check for best fit

and

least waste. This process can achieve 10-15% waste reduction.

AppliCad's Roof Wizard generates the cutting details for every single

panel, taking account of lap side and

direction of lay. A detailed set

of reports is produced to guide the installers. They know how big and at

what

angle each panel is to be cut, and where on the roof plan that panel

is to installed. No errors and absolutely

minimum waste.

Simply mark and cut as indicated - quick and easy.

The portable pivot

shear from Swenson provides

the hardware to take full advantage of this very

clever AppliCad system.

These portable

hand shears save significant time over alternative methods of jobsite

panel shearing

and leave a straight, clean edge. These hand operated cutters

are easily moved between job sites.

Models are available for shearing

hips

and valleys at any roof slope. Replacement blades are available

for hundreds

of panel profiles and can be changed in 10 minutes or less. Shear exposed

fastener,

snap lock, standing seam, sheet metal, shingles, siding, soffit,

metal tile or sheets of plastic, vinyl,

fiberglass, stainless steel as

well as other materials. This method is much faster than using a nibbler

and leaves a much cleaner edge than a metal cutting saw blade.

And the final result looks great!

Faster, cleaner, safer, cheaper!

Follow this link to news of Swenson's latest new gadget for roofers - The Snap Table Hemmer.

The Principle of Helping Customers

All our customers are important. Size of the business is not an issue,

nor the number of operators.

When you invest in AppliCad software you have

made one of the most important investments in

your business. The customer

service team know that and accept the responsibility to you to help

make

it a productive tool

in your business.

Call us if you need help. That is what we're here for.